| PRODUCTION PROCESS All processes from order to graphic design, from printing to delivery are precisely followed by our experienced team and maximum effort is made for perfect label printing. In our production using high quality raw materials, first class paints and technological equipment, our professional staff and sensitive quality control team work to achieve the most perfect result in label production processes. |

|

|

CUSTOMER REPRESENTATIVES For printing solutions that will vary according to the sector to be used and the type of packaging to be applied, our experienced sales team will provide you with all the information you need. Our customer representatives carry out the manufacturing processes in label printing in synchronisation with the production team and inform the customer about the whole process. |

| CLASS & MOULD The designs are sent to the cliché by our graphics department after the final controls are made. The prepared designs pass through the 'Computerised Control System' and the plate and mould are prepared. With the help of 'Computerised Control System', a perfect printing work is carried out by minimising human errors. Clichés for Flexo, Letterpress, Offset printing machines are exposed, washed and made ready for printing. |

|

|

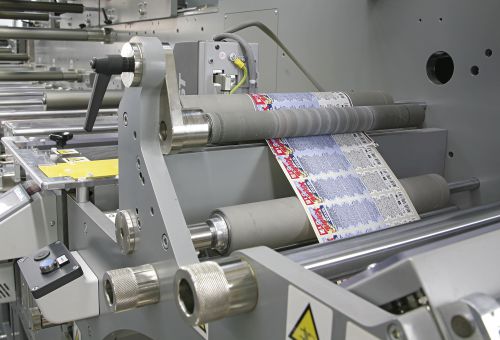

PROFESSIONAL PRINTING We combine your packaging with quality printing in our production facility equipped with modern technology machines. In our production facility where Flexo, Serigraph, Offset and Digital Printing techniques are used, our 8 colour capacity machines have the ability to make hot-cold gilding and embossing. These machines can print on 12 micron to 350 gr. paper and filmic materials. The most suitable material and printing technique are used by considering the surface and ambient conditions on which the label will be applied. |

| GRAPHIC & DESIGN Our professional graphic design team works with you to achieve the packaging you need. Our graphic design department combines their knowledge and skills with creativity to provide our customers with professional designs and different choices. All details from the instructions for use on the label to the colours to be used are carried out with the approval of the customers. |

|

|

FAST DELIVERY As one of the most important cornerstones of customer-oriented work, fast service logic is carried out in our company with highly professional time adjustments and customer mapping. With the awareness that the prolongation of the deadline will cause disruption of your production, delivery is provided in a planned and safe manner. |