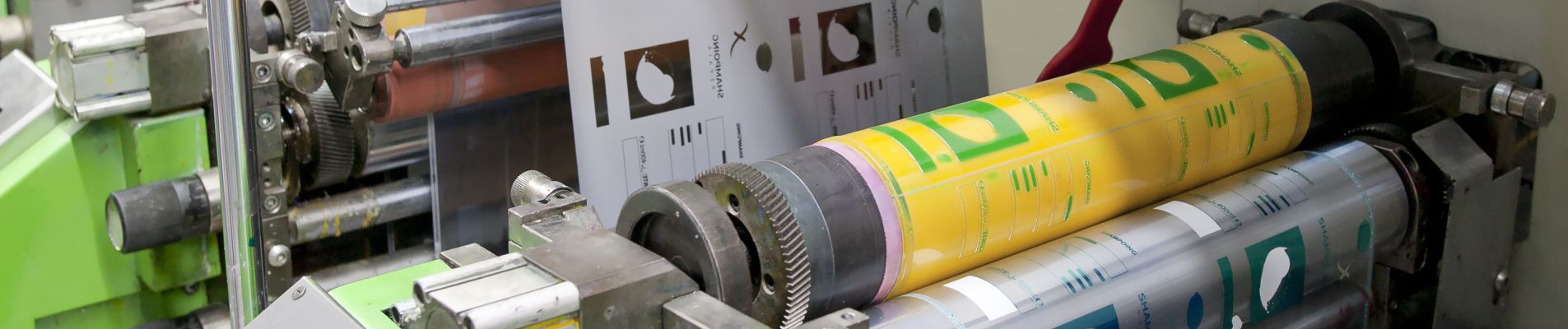

| SECONDARY PRINTING SYSTEMS Labels can be subjected to post-printing processes such as cellophane, lacquer, embossed lacquer, gilding, etc. depending on the good appearance, corporate integrity, shelf selectivity or the characteristics of the product to be used. The parts determined in the planning stage are made ready for printing during the graphic design process. All post-printing processes are applied smoothly in our technological machines |

|

|

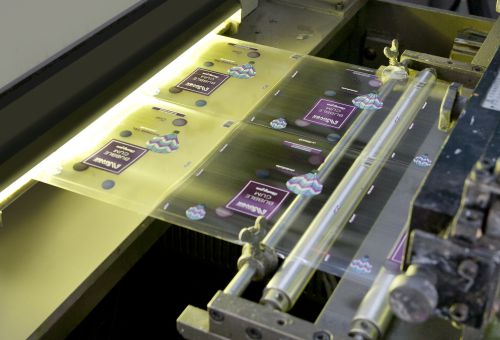

EMBOSSED PRINTING Embossed printing, also called embossed lacquer, is used to add dimension to the design. If embossing is done in the part that is most desired to be highlighted in the image, depth and remarkable feature is gained. The printed labels are processed in embossed printing machines and directed to special cutting machines, which is the last stage. Emboss applications on labels are made in silk screen printing machines. |

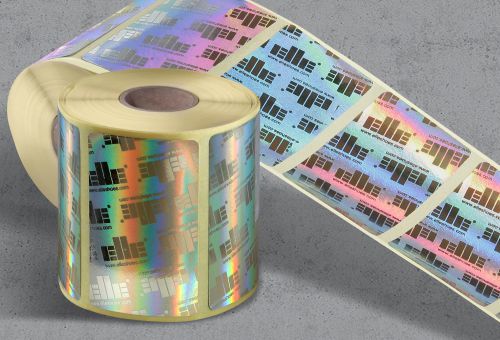

| HOLOGRAM Holograms, in general, are several-dimensional images in which objects can be seen from different angles under the right lighting, as in reality. It adds more value to the printed work applied and creates an image on the consumer that the product is "quality, luxury, valuable". It is impossible to imitate hologram labels, which you can choose to prevent packaging fraud. It cannot be reproduced by photocopy and scanners. |

|

|

HOT GILDING Hot foil stamping has a very important place among the methods applied after printing. The effect of the visuals on the packaging on the consumer is a fact that can be accepted by everyone. If the material used is applied in the right place, with the right method and colour integrity is ensured, it gives visual appeal and difference to printed products. |

| CELLOPHANE It is a thin gelatine coated on the printing surface by plastering to protect the materials from external factors (sun, moisture, oil, etc.). While matt cellophane creates a matt effect on labels, glossy cellophane creates a shiny effect. Partial lacquer or embossing can be applied to the printed labels after cellophane. |

|

|

PARTIAL LACQUER It is a process that can be performed on the entire or optionally only a part of the surface to be printed. It gives the printed material the effect of gloss or opaqueness. Lacquer also protects the label against external factors. The lacquered paper surface is highly resistant to scratching, moisture, sunlight and dispersion of the print on the paper. |